Zebra ZE511 & ZE521 Print Engines: Powering High-Volume Barcode Printing

Posted by The ZPS Store on Oct 18th 2025

In the fast-paced world of manufacturing, logistics, and supply chain management, barcode labeling isn't just a task—it's a critical process that can make or break operational efficiency.

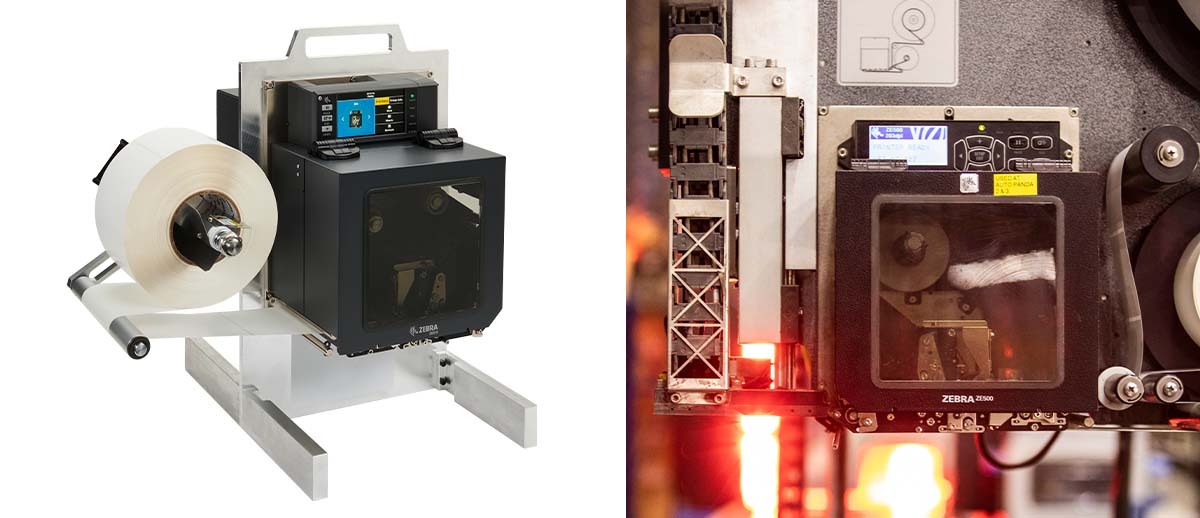

Enter the print engine, a specialized type of barcode printer designed for seamless integration into automated systems. Unlike traditional tabletop barcode printers, which are standalone units meant for manual or semi-manual use, a print engine is essentially the "brain" of a larger labeling setup. It's engineered to be mounted directly onto a label applicator or conveyor line, enabling automated label printing and application in real time.

So, How is a Print Engine Used?

Picture a production line where products zoom by on a conveyor belt. The print engine receives data from your enterprise system—say, a unique barcode for tracking—and prints it onto a label. Paired with a label applicator, it then automatically applies that label to the product, box, or pallet without human intervention. This setup is ideal for environments demanding high-speed, high-volume output, where stopping to hand-apply labels would create bottlenecks.

Why Choose a Print Engine Over a Typical Tabletop Barcode Printer?

Tabletop models, like Zebra's popular ZD series, are great for low-to-medium volume tasks in offices or small warehouses. They're compact, user-friendly, and cost-effective for printing a few hundred labels a day. However, in industrial settings with thousands of labels needed per shift, they fall short. Print engines excel in durability, speed, and integration, handling 24/7 operations without frequent downtime. They reduce labor costs by automating the process, minimize errors from manual handling, and boost throughput. For businesses dealing with high-volume barcode printing, switching to a print engine with label auto apply can transform hand labeling drudgery into a streamlined, error-free operation. If you're still relying on hand labeling for large batches, the inefficiency in time and accuracy can add up quickly, making print engines a smart upgrade for scaling operations.

When it comes to leading the pack in high-volume industrial barcode printing, the Zebra ZE511 printer and Zebra ZE521 printer stand out as top contenders. These Zebra print engines are built for demanding environments, combining exceptional output capacity with advanced automation features. What sets them apart is their ability to deliver massive label volumes—up to 18 inches per second (ips) on the ZE511—while integrating flawlessly with label applicators. This print engine and label applicator combination drives efficiency to new heights, allowing businesses to handle peak demands without sacrificing quality. In industries where every second counts, like e-commerce fulfillment or automotive manufacturing, the ZE511 and ZE521 minimize downtime and maximize productivity, making them a go-to choice for automated labeling systems.

Key Features and Functionalities of the Zebra ZE511 / ZE521

The Zebra ZE511 and ZE521 are packed with features that cater to industrial needs, starting with their rugged durability. Constructed from all-metal components, these print engines are designed to withstand harsh environments, including dust, moisture, and constant vibration on production lines. This build quality ensures they can run 24/7/365 without skipping a beat, a must for non-stop operations in warehouses or factories.

- Resolution options are flexible, with DPI selections of 203, 300, and even 600 dpi on the ZE511 for ultra-sharp barcodes and text—perfect for compliance labels requiring fine details.

- Print width varies by model: the ZE511 offers a 4.09-inch maximum, ideal for standard labels, while the ZE521 extends to 6.6 inches for wider applications like shipping pallets.

- Print speeds are impressive, with the ZE511 hitting 18 ips at 203 dpi, 14 ips at 300 dpi, and 6 ips at 600 dpi. The ZE521 isn't far behind, reaching 14 ips at 203 dpi and 12 ips at 300 dpi, ensuring high output even for larger labels.

- Orientation flexibility is another highlight—available in left-hand or right-hand configurations, these printers adapt to your line setup without custom modifications. This versatility reduces installation time and costs.

- On the tech side, they include 1 GB DRAM and 2 GB Flash memory, supporting complex print jobs and RFID encoding for smart labels.

- Zebra's Print DNA software suite enhances functionality with remote management, security features, and easy integration into existing systems like ERP or WMS.

When it comes to total cost of ownership (TCO), the ZE511 and ZE521 shine. Tool-less maintenance—such as quick-release printheads and platens—means swaps take seconds, not hours, cutting downtime and repair costs. Bluetooth connectivity and USB host ports simplify setup, while the 4.3-inch color LCD touch screen provides intuitive status monitoring. Overall, these features contribute to lower TCO through reliability, reduced consumable waste, and extended lifespan, making them a cost-effective choice for high-volume label printing.

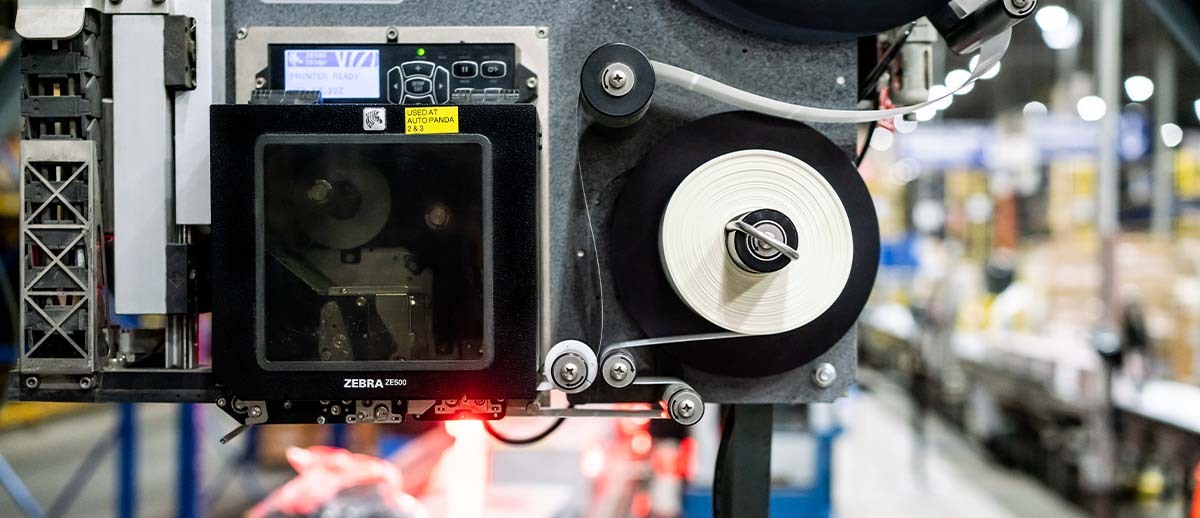

Building on a Legacy: From PAX4 and ZE510 to the ZE511/ZE521

The Zebra ZE511 and ZE521 didn't emerge in a vacuum; they build directly on the success of previous models like the ZE510 (part of the ZE500 series) and the older PAX4 print engine series. The PAX4, a pioneer in print engines, was known for its reliability but lacked modern conveniences like rotatable displays and advanced software. The ZE500 series improved on this with better ease of use, such as a graphical display that could be positioned flexibly, and enhanced integration for print-and-apply systems.

The ZE511 and ZE521 take these foundations further. Compared to the ZE510, they offer faster print speeds (up from 12-14 ips to 18 ips on the ZE511), the addition of 600 dpi resolution on the 4-inch model, and Print DNA for smarter operations. Maintenance is expedited with tool-less printhead removal, a step up from the ZE500's design. RFID capabilities are more robust, with on-metal tag support in some configurations. From the PAX4, they've inherited durable construction but added modern touches like Bluetooth, a touch interface, and evolving intelligence for predictive maintenance. These improvements make the ZE511/ZE521 more future-proof, ensuring they handle today's high-volume demands while adapting to tomorrow's tech.

Key Differences Between the ZE511 and ZE521

While both models share core strengths, the primary differences lie in size and capabilities. The Zebra ZE511 printer is the 4-inch version, optimized for standard labels with options up to 600 dpi for high-precision printing. It's slightly faster at lower resolutions, making it ideal for compact setups. The Zebra ZE521 printer, on the other hand, handles wider 6-inch prints but tops out at 300 dpi, suiting applications like pallet labeling where speed over ultra-fine detail is key. Both support thermal transfer and direct thermal methods, but the ZE521's broader width accommodates larger media, influencing your choice based on label size needs.

Common Applications and Use Cases

The ZE511 and ZE521 excel in scenarios requiring high-volume industrial barcode printing with automation. In manufacturing, they're used for product identification, where labels are auto-applied to components on assembly lines. Logistics and warehousing benefit from their speed in shipping and receiving, applying barcodes to boxes for seamless tracking. Healthcare and pharmaceuticals rely on them for compliance labeling, ensuring accurate, durable tags on vials or packages. E-commerce fulfillment centers use them to handle peak-season volumes, reducing hand labeling errors. Overall, any operation transitioning from manual hand labeling to label auto apply will see gains in these Zebra print engines.

How the ZE500 Series Stacks Up Against Competitors

Compared to competitive print engine models from brands like Sato, Honeywell, and TSC/Printronix, the Zebra ZE500 series (including ZE511/ZE521) holds a strong position in function and features. Here's how it measures up against key contenders:

- Sato S84-ex and S86-ex Series: These print engines offer 4-inch (S84-ex) and 6-inch (S86-ex) print widths, with 203/305 dpi resolutions and speeds up to 14 ips. They feature tool-less maintenance and robust RFID encoding, similar to Zebra, but lack 600 dpi options. Sato's AEP (Application Enabled Printing) allows standalone operation, which Zebra matches with Print DNA's remote management. Sato's modular drive system minimizes downtime, but Zebra's faster 18 ips speed (ZE511) and intuitive touch interface give it an edge for high-throughput setups.

- Sato Lt408: A more budget-friendly 4-inch engine (203 dpi, 6 ips), this model targets lighter industrial use. It supports basic RFID but lacks the speed and resolution versatility of the ZE511/ZE521. While cost-effective (starting ~$2,500), it can't match Zebra's 24/7 durability or advanced software ecosystem, making it less ideal for peak-demand environments.

- Honeywell A-Class Mark II (A-4212/A-6212): These 4-inch and 6-inch engines provide 203–600 dpi and up to 12 ips, matching Zebra's resolution range but trailing in speed. Honeywell's stainless-steel build ensures durability in harsh conditions, and PL-Z emulation simplifies integration with legacy systems. However, Zebra's Print DNA offers superior remote monitoring and security, and its tool-less maintenance is faster, potentially lowering TCO. Honeywell's pricing (~$3,000–$5,500) is comparable, but Zebra's orientation flexibility (left/right-hand) adds installation ease.

- TSC/Printronix PEX Series (e.g., PEX2412/PEX3612): These 4-inch and 6-inch modules deliver 203–600 dpi and up to 14 ips, with strong RFID and optional inline barcode verification (ODV-2D). TSC/Printronix emphasizes affordability (~$2,500–$4,500) and low-noise operation, appealing for e-commerce or retail. Their PSA platform aids migration, but Zebra's higher speed (18 ips) and Print DNA's predictive maintenance give it a slight edge in high-volume scenarios. TSC's verification tech is a plus for compliance-heavy sectors, though.

Zebra's ZE511/ZE521 excels in speed (18 ips vs. competitors' 12–14 ips) and software integration, making it a top pick for seamless print-and-apply systems. While Sato and TSC/Printronix can be more budget-friendly, and Honeywell offers robust precision, Zebra's ecosystem reduces training and support needs, often justifying its price (~$3,000–$5,000). In user reviews, Zebra consistently ranks high for reliability and ease of use in industrial barcode printing.

5 Questions to Consider Before Investing in a Print Engine Label Applicator System

If you're an end-user with high label printing volume but still relying on hand labeling, pondering a shift to an automated system like the Zebra print engine with label applicator could be transformative. Here are five key questions to guide your decision:

- What's your current daily label volume, and how is it projected to grow? If you're printing thousands of labels manually, automation could handle spikes without adding staff, preventing bottlenecks.

- How much are labor costs eating into your budget for hand labeling?Calculate wages, training, and overtime—auto apply systems often pay for themselves in 6-12 months by freeing workers for higher-value tasks.

- What error rates are you experiencing with manual application?

Hand labeling invites misplacements or scans fails; print engines ensure precision, reducing returns and compliance issues. - Can the system integrate with your existing software and hardware?

Check compatibility with your ERP or conveyor lines—Zebra's Print DNA makes this seamless, but assess upfront. - What's the potential ROI, including downtime reduction and efficiency gains? Factor in TCO savings from durability and speed; tools like Zebra's calculators can help quantify benefits.

The Zebra ZE511 printer and Zebra ZE521 printer represent the pinnacle of print engine technology for high-volume industrial barcode printing. By automating label auto apply and ditching inefficient hand labeling, businesses can achieve unprecedented productivity. Whether you're upgrading from older models or entering the world of automated labeling systems, these Zebra print engines offer durability, speed, and smarts to keep your operations running smoothly. If efficiency is your goal, investing in this tech could be the game-changer your workflow needs.

Talk to an Expert